Cummins Diesel Generator Parts: An In-Depth Analysis of Essential Components

Introduction: Cummins is renowned for its high-quality diesel generators that offer reliable power solutions for various industries. To better understand the inner workings of these robust machines, it's crucial to explore their integral components. In this comprehensive guide, we delve into the various Cummins diesel generator parts, their functions, and their significance in ensuring optimal performance.

Cummins Diesel Generator Parts

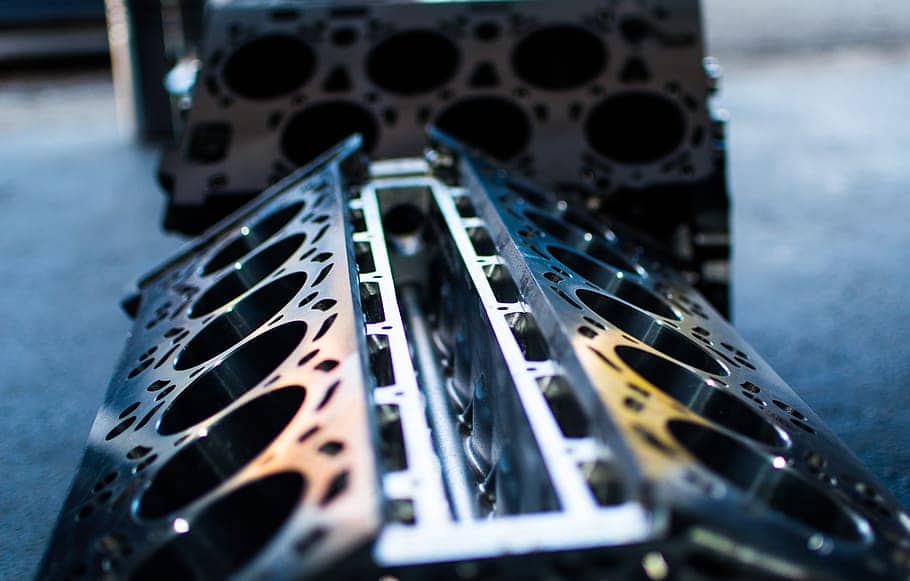

Engine Block:

The engine block is a vital component of the Cummins diesel generator. Usually made of cast iron, it serves as the main structural foundation of the engine. The engine block houses various critical components, including the cylinders, crankshaft, camshaft, and piston assembly. It provides support and stability for these components, ensuring proper alignment and functionality.

Functions of the engine block

In addition to structural support, the engine block features coolant passages. These passages allow the circulation of coolant to regulate the engine's operating temperature. The heat generated during combustion is dissipated through the engine block, preventing overheating and maintaining optimal performance.

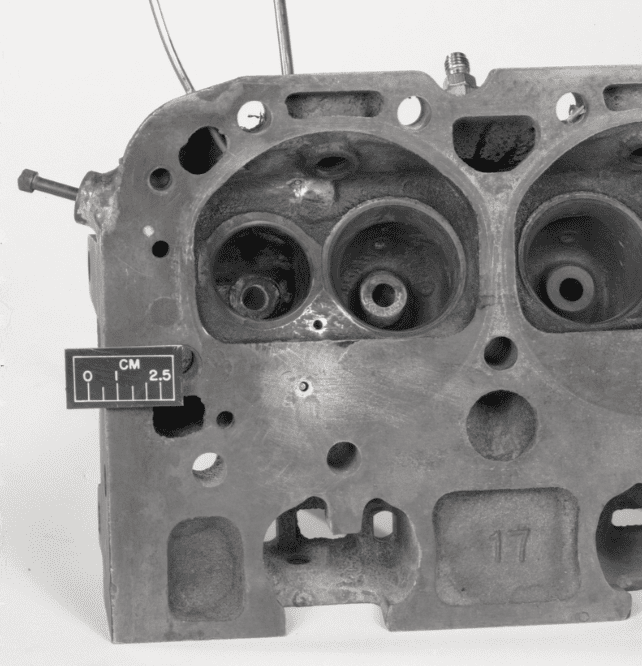

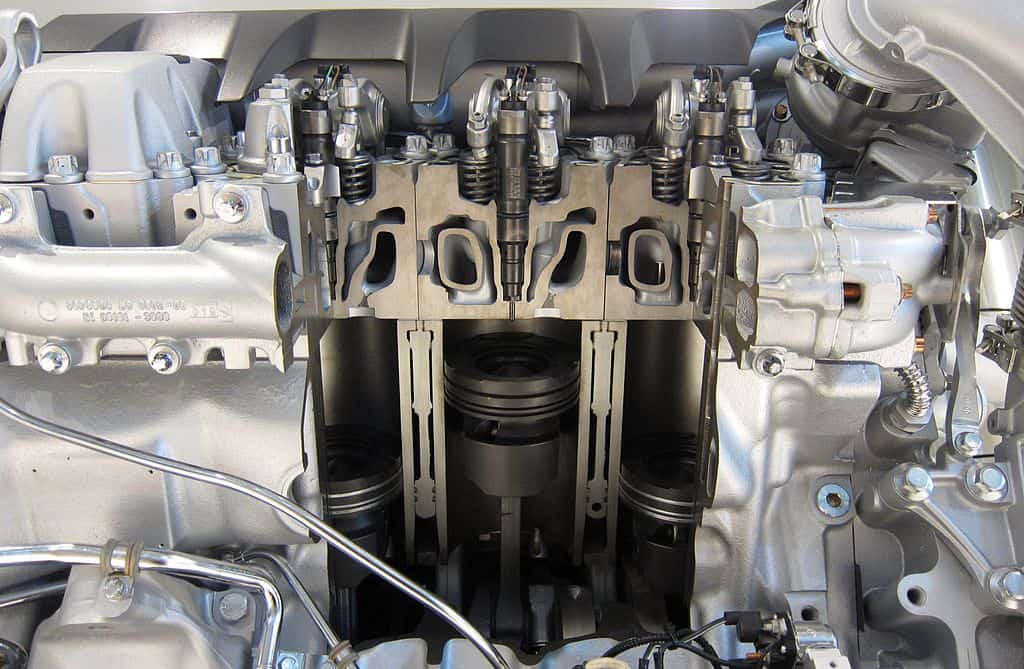

Cylinder Head:

Situated on top of the engine block, the cylinder head seals the combustion chamber. It houses the intake and exhaust valves, fuel injectors, and, if applicable, glow plugs. The cylinder head's primary function is to regulate the flow of the air-fuel mixture into the combustion chamber and facilitate the expulsion of exhaust gases.

Functions of cylinder head

The intake valves allow the entry of fresh air or air-fuel mixture, while the exhaust valves enable the discharge of combustion byproducts. Fuel injectors, positioned in the cylinder head, precisely deliver fuel into the combustion chamber. If present, glow plugs assist in cold starting by heating the air-fuel mixture for easier ignition.

Piston Assembly:

The piston assembly is a crucial part of the engine's combustion process. It consists of several components, including the piston, piston rings, piston pin, and connecting rod. During engine operation, the piston moves up and down within the cylinder, driven by the force generated from combustion.

Functions of Piston Assembly:

The piston rings, positioned around the piston, provide a tight seal between the piston and the cylinder walls. This seal prevents the escape of combustion gases, ensuring maximum pressure and efficiency within the combustion chamber. The piston pin connects the piston to the connecting rod, enabling the transfer of force from the piston to the crankshaft.

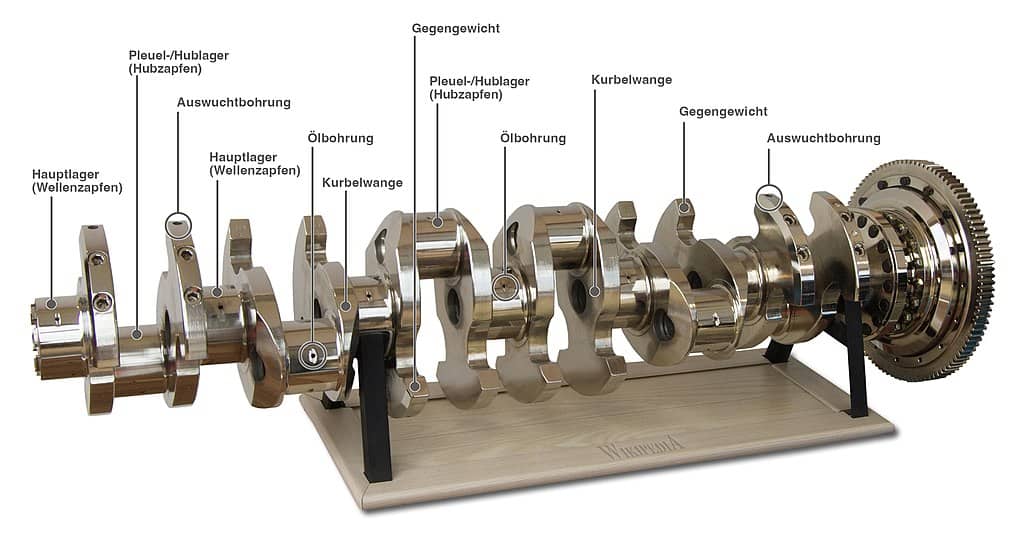

Crankshaft:

The crankshaft is responsible for converting the reciprocating motion of the piston into rotational motion. It is a robust, precisely engineered component that connects to the connecting rods. As the pistons move up and down, the connecting rods transfer this motion to the crankshaft. The crankshaft then converts this linear motion into a rotating motion.

Functions of Crankshaft

The rotational motion of the crankshaft drives other engine components, such as the camshaft and generator rotor, ultimately producing electrical power. It is designed to withstand high levels of stress and torque, ensuring smooth and reliable engine operation.

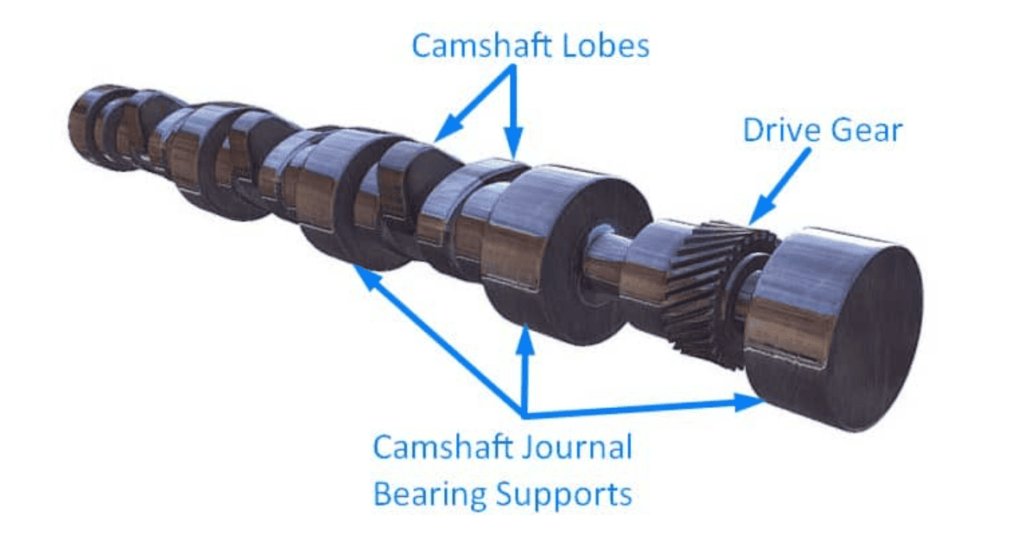

Camshaft:

The camshaft is a critical component that controls the opening and closing of the engine's valves. It works in synchronization with the crankshaft, ensuring precise timing and operation of the valves. The camshaft features lobes or cams that push against the valves, causing them to open and close at the appropriate moments.

Functions of Camshaft

The intake valves open to allow the entry of fresh air or air-fuel mixture into the combustion chamber during the intake stroke. The exhaust valves open to release the combustion byproducts during the exhaust stroke. The camshaft's correct timing and operation are essential for optimal engine performance, fuel efficiency, and power output.

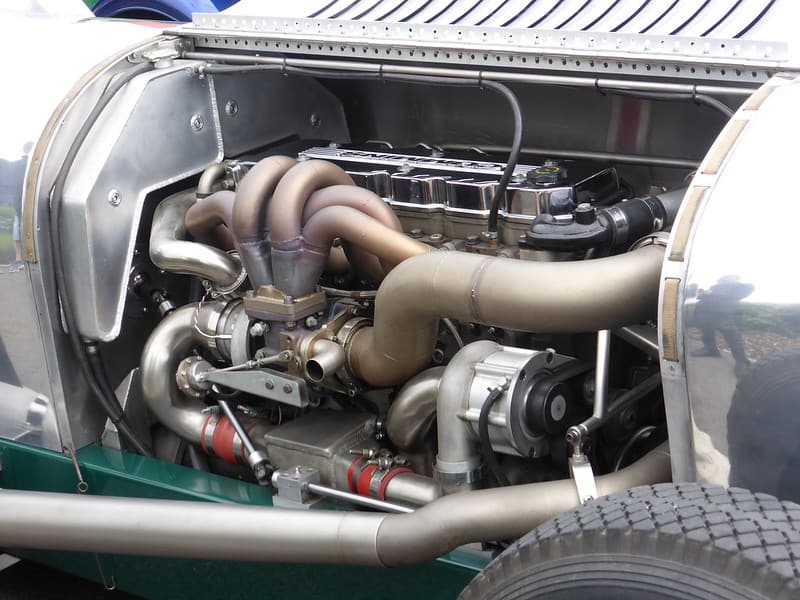

Turbocharger:

The turbocharger is an additional component that enhances the engine's power output. It operates on the principle of forced induction, utilizing exhaust gas energy to drive a turbine. This turbine, in turn, compresses the incoming air before it enters the combustion chamber.

Functions of Turbocharger

By compressing the intake air, the turbocharger increases its density, resulting in better combustion efficiency. This leads to improved power output and reduced fuel consumption. The turbocharger allows the engine to produce more power without significantly increasing its size or weight.

Fuel Injection System:

The fuel injection system in a Cummins diesel generator is responsible for precise fuel delivery into the combustion chamber. It comprises components such as fuel injectors, fuel pump, and fuel filters. The fuel injectors atomize the fuel, breaking it down into fine droplets for efficient combustion.

Functions of Fuel Injection System:

The fuel pump ensures that the fuel is delivered at the correct pressure to the injectors. It draws fuel from the fuel tank and supplies it to the injectors based on the engine's demand. Fuel filters are incorporated to remove any impurities or contaminants present in the fuel, ensuring clean and reliable fuel delivery.

Cooling System:

The cooling system in a Cummins diesel generator prevents overheating of the engine and maintains optimal operating temperatures. It consists of various components, including the radiator, coolant reservoir, water pump, and thermostat.

Functions of Cooling System:

The water pump circulates coolant through the engine, absorbing heat generated during combustion. The heated coolant is then transferred to the radiator, where it is cooled by the airflow. The thermostat regulates the coolant flow, allowing it to circulate when the engine reaches the ideal temperature. The coolant reservoir provides a storage space for the coolant and allows for expansion and contraction as temperatures fluctuate.

Exhaust System:

The exhaust system is responsible for the safe and efficient disposal of combustion byproducts from the engine. It includes components such as the exhaust manifold, catalytic converter (if applicable), muffler, and exhaust pipe.

Functions of Exhaust Systems

The exhaust manifold collects the exhaust gases from each cylinder and directs them into a single pipe. In some cases, a catalytic converter may be incorporated to reduce harmful emissions by converting pollutants into less harmful substances. The muffler helps reduce exhaust noise by utilizing sound-absorbing materials. Finally, the exhaust pipe directs the exhaust gases away from the engine and releases them into the atmosphere.

Electrical System:

The electrical system in a Cummins diesel generator is essential for generating, regulating, and distributing electrical power. It comprises components such as the generator alternator, voltage regulator, control panel, wiring harnesses, and battery.

Functions of Electrical System:

The generator alternator is responsible for converting mechanical energy from the engine into electrical power. The voltage regulator ensures a stable and consistent voltage output. The control panel provides operators with the necessary controls and monitoring systems for the generator. Wiring harnesses connect various electrical components, while the battery provides initial power for starting the generator and serves as a backup power source if needed.

Summary - Cummins Diesel Generator Parts

Each part of a Cummins diesel generator plays a crucial role in its overall functionality and performance. From the engine block to the electrical system, these components work together to generate power, ensure combustion efficiency, regulate temperatures, control emissions, and deliver reliable electrical output. Understanding the functions of these parts helps in maintaining, troubleshooting, and optimizing the performance of Cummins diesel generators in various applications.

FAQs Cummins Diesel Generator Parts

Q: What are the common wear and tear parts in a Cummins diesel generator?

A: Common wear and tear parts in a Cummins diesel generator include piston rings, gaskets, fuel filters, air filters, and belts. These parts require regular inspection and replacement to ensure optimal performance and prevent breakdowns.

Q: How often should I change the fuel filters in my Cummins diesel generator?

A: The frequency of fuel filter changes depends on various factors such as the operating conditions and fuel quality. As a general guideline, it is recommended to change the fuel filters every 500 hours of operation or as specified by the manufacturer.

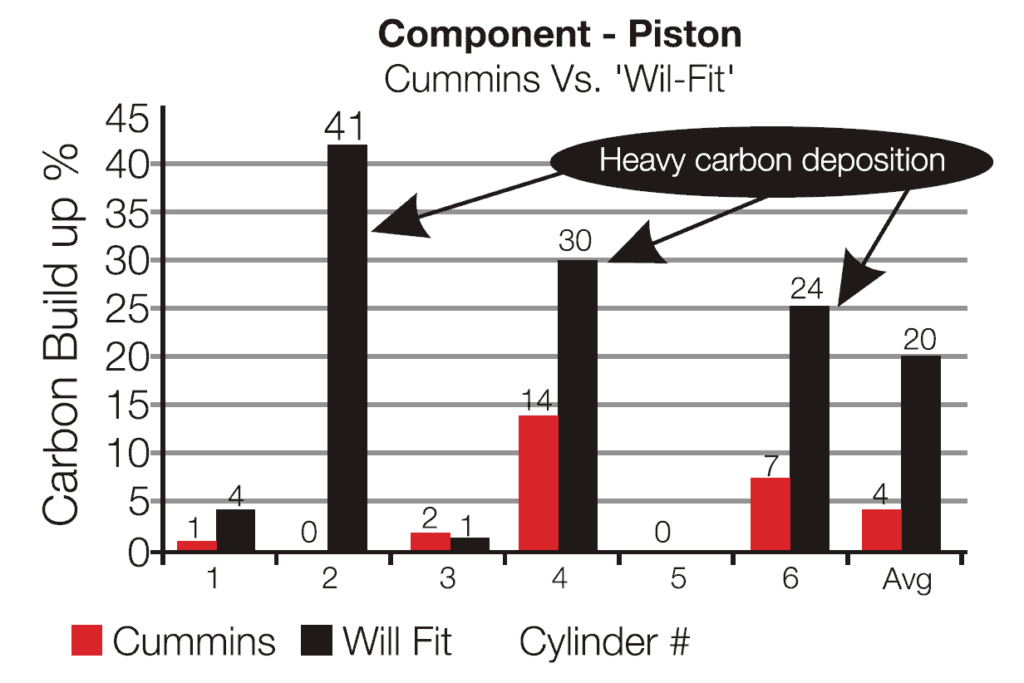

Q: Can I use aftermarket parts for my Cummins diesel generator?

A: While aftermarket parts are available for Cummins diesel generators, it is recommended to use genuine Cummins parts. Genuine parts are specifically designed and tested for compatibility and performance, ensuring the longevity and reliability of your generator.

Q: What should I do if my Cummins diesel generator is overheating?

A: If your Cummins diesel generator is overheating, first check the coolant level and ensure there are no coolant leaks. Inspect the radiator for debris or obstructions that may be blocking airflow. Additionally, check the operation of the water pump and thermostat. If the issue persists, it is advisable to contact a qualified technician for further diagnosis and repair.

Q: How often should I inspect the generator's electrical connections?

A: Regular inspection of the generator's electrical connections is crucial for safety and performance. It is recommended to inspect the connections at least once a year or whenever maintenance is performed. Look for signs of corrosion, loose connections, or damaged wires and rectify any issues promptly.

Q: What is the purpose of a glow plug in a Cummins diesel generator?

A: Glow plugs are used in some Cummins diesel generators to assist with cold starting. They heat the air-fuel mixture inside the combustion chamber, making ignition easier in cold conditions. Glow plugs are typically activated during engine startup and automatically turn off once the engine reaches operating temperature.

Q: Are there any specific maintenance tasks for the turbocharger in a Cummins diesel generator?

A: The turbocharger in a Cummins diesel generator requires regular inspection and maintenance. It is important to check for any signs of excessive wear, oil leaks, or abnormal noise. Regular cleaning of the air intake system and changing the air filters can help prevent debris accumulation in the turbocharger.

Q: Can I use additives in the fuel for my Cummins diesel generator?

A: It is generally recommended to avoid using fuel additives in Cummins diesel generators unless specifically recommended by the manufacturer. Fuel additives may interfere with the fuel system components and could void warranty coverage. It is best to consult the manufacturer or a qualified technician for guidance on fuel additives.

Q: How do I determine the correct belt tension for my Cummins diesel generator?

A: Proper belt tension is crucial for optimal generator performance. Refer to the manufacturer's specifications for the recommended belt tension. Use a tension gauge to measure the tension and adjust as necessary. Improper belt tension can lead to belt slippage, reduced power output, and premature wear.

Q: What should I do if my Cummins diesel generator is not starting?

A: If your Cummins diesel generator is not starting, check the battery for sufficient charge and ensure the fuel tank has an adequate fuel supply. Inspect the fuel filters for clogs and verify that the fuel shut-off valve is open. If the issue persists, it is recommended to contact a qualified technician for further diagnosis and repair.

Cummins Diesel Generator Parts and Functions Pdf

click here to download Cummins Diesel Generator Parts and Functions Pdf