Introduction

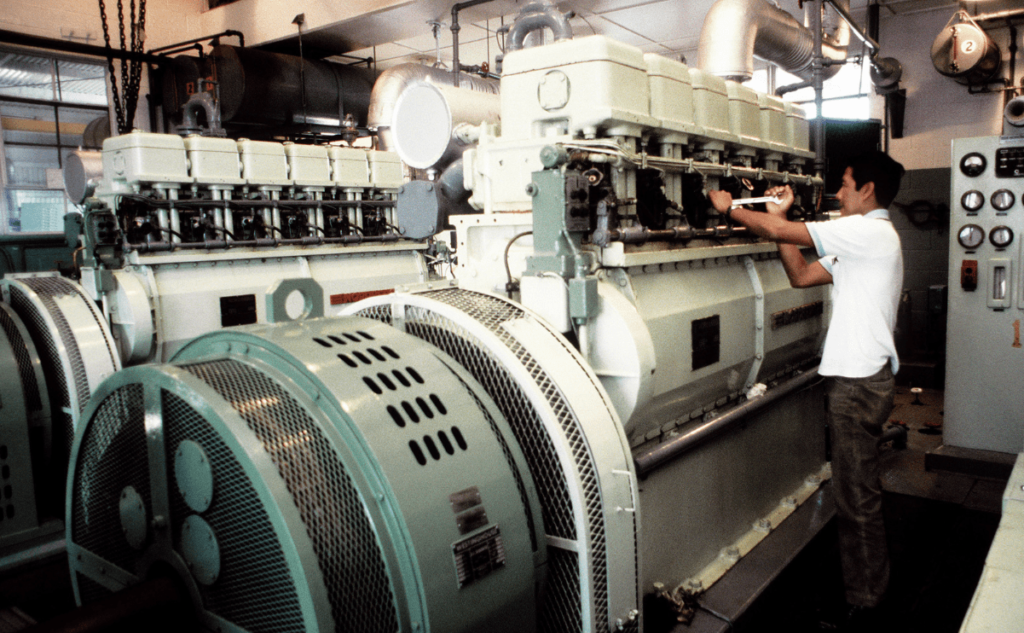

Diesel generators are widely used in industrial, commercial, and residential settings as a reliable source of backup power. To ensure the reliable operation of diesel generators, regular maintenance is essential. Maintenance can prevent unplanned downtime, extend the life of the generator, and reduce maintenance costs over time. In this article, we will discuss some of the key aspects of diesel generator maintenance.

Diesel Generator Maintenance Checklist

A maintenance checklist is a useful tool that can help you ensure that all necessary maintenance tasks are completed on time. Here is a checklist that covers some of the key maintenance tasks for diesel generators:

- Change oil and oil filter

- Replace fuel filters

- Check air filters and clean or replace if necessary

- Check and tighten all electrical connections

- Inspect and clean the cooling system

- Inspect and test the batteries

- Test the generator under load

- Inspect the generator for signs of wear and tear

- Lubricate moving parts

- Test and maintain the automatic transfer switch (ATS) and control panel

Diesel Generator Maintenance Cost

The cost of diesel generator maintenance can vary depending on the size and type of the generator, as well as the frequency and extent of maintenance required. However, regular maintenance can actually reduce overall maintenance costs over time by preventing more serious issues from developing. Neglecting maintenance can lead to costly repairs and downtime, which can be avoided through regular upkeep.

Diesel Generator Maintenance Schedule

A maintenance schedule outlines when different maintenance tasks should be completed. It can be based on factors such as the age of the generator, its usage, and the manufacturer's recommendations. Here is an example of a maintenance schedule for a diesel generator:

- Daily: Check oil level, coolant level, and fuel level

- Weekly: Inspect and clean air filters, check battery charger, check battery electrolyte level

- Monthly: Change oil and oil filter, replace fuel filters, inspect coolant system, check starter motor, alternator, and belts

- Quarterly: Load test the generator, inspect and clean the battery, inspect the cooling system, check and adjust the fuel injection timing

- Semi-annually: Inspect the exhaust system, inspect and clean the fuel system, inspect the governor and speed control

- Annually: Replace the air filter, inspect and clean the fuel tank, inspect and replace the spark plugs (if applicable)

Diesel Generator Maintenance Chart

A maintenance chart is a visual tool that can help you track maintenance tasks over time. It can be used in conjunction with a maintenance log book (see below) to help ensure that maintenance is completed on schedule. Here is an example of a maintenance chart:

| Maintenance Task | Daily | Weekly | Monthly | Quarterly | Semi-annually | Annually |

|---|---|---|---|---|---|---|

| Check oil level | X | |||||

| Check coolant level | X | |||||

| Check fuel level | X | |||||

| Inspect and clean air filters | X | |||||

| Change oil and oil filter | X | |||||

| Replace fuel filters | X | |||||

| Load test generator | X | |||||

| Inspect exhaust system | X | |||||

| Replace air filter | X |

Diesel Generator Maintenance Log Book

A maintenance log book is a record of all maintenance tasks completed on the generator. It can help you keep track of when maintenance was last performed, identify trends or recurring issues, and provide a history of the generator's maintenance.

Here is an example of a Diesel Generator Maintenance Log Book:

| Date | Maintenance Task | Technician | Comments |

|---|---|---|---|

| 01/01/2022 | Changed oil and oil filter | John Doe | |

| 01/07/2022 | Replaced fuel filters | Jane Smith | |

| 02/01/2022 | Inspected and cleaned air filters | John Doe | |

| 03/15/2022 | Load tested generator | Jane Smith | |

| 05/01/2022 | Replaced air filter | John Doe | |

| 06/01/2022 | Inspected exhaust system | Jane Smith | |

| 07/01/2022 | Changed oil and oil filter | John Doe | |

| 07/15/2022 | Replaced battery | Jane Smith | |

| 08/01/2022 | Inspected and cleaned fuel system | John Doe | |

| 09/01/2022 | Load tested generator | Jane Smith | |

| 10/01/2022 | Inspected and cleaned cooling system | John Doe | |

| 11/01/2022 | Replaced spark plugs | Jane Smith | |

| 12/01/2022 | Inspected and tightened electrical connections | John Doe |

Diesel Generator Maintenance Checklist

- Check the oil level and quality: Check the oil level regularly and change it according to the manufacturer's recommendations. Use high-quality oil to ensure proper lubrication of the engine.

- Inspect the air filter: A dirty or clogged air filter can reduce engine performance and increase fuel consumption. Inspect and clean or replace the air filter as necessary.

- Check the fuel system: Check the fuel filter, lines, and tank for signs of damage or leaks. Replace the fuel filter regularly to prevent engine damage.

- Inspect the cooling system: Check the radiator, hoses, and coolant level. Clean the radiator fins and replace the coolant according to the manufacturer's recommendations.

- Check the battery: Inspect the battery terminals and connections for signs of corrosion. Test the battery voltage and replace it if necessary.

- Inspect the exhaust system: Check the exhaust manifold, muffler, and pipes for signs of damage or leaks. Replace any damaged components.

- Check the generator's electrical system: Inspect the wiring, connections, and fuses for signs of damage or wear. Tighten loose connections and replace any damaged components.

- Load test the generator: Perform a load test to ensure that the generator can handle its rated load. This will also help identify any potential issues before they become a problem.

- Inspect the engine and generator mounts: Check the engine and generator mounts for signs of wear or damage. Replace any damaged mounts to prevent excessive vibration.

- Perform a general inspection: Check the generator for any signs of wear or damage, such as loose bolts or rust. Clean the generator and enclosure as necessary.

| Maintenance Task | Frequency/Time Period |

|---|---|

| Check oil level and quality | Every 50-100 hours or as recommended by manufacturer |

| Inspect air filter | Every 100-200 hours or as recommended by manufacturer |

| Check fuel system | Every 100-200 hours or as recommended by manufacturer |

| Inspect cooling system | Every 200-500 hours or as recommended by manufacturer |

| Check battery | Every 200-500 hours or as recommended by manufacturer |

| Inspect exhaust system | Every 500-1000 hours or as recommended by manufacturer |

| Check electrical system | Every 500-1000 hours or as recommended by manufacturer |

| Load test generator | Every 500-1000 hours or as recommended by manufacturer |

| Inspect engine and generator mounts | Every 500-1000 hours or as recommended by manufacturer |

| Perform general inspection | Every 1000-2000 hours or as recommended by manufacturer |

By following this maintenance schedule, you can ensure that all necessary maintenance tasks are completed on time to help prevent unexpected breakdowns and ensure the reliable operation of your diesel generator.

PDF Downloads

- Diesel Generator Maintenance: Click to download PDF (Source: cummins.com)

- Diesel Generator Maintenance Checklist Pdf: Click to Download PDF

Conclusion

In conclusion, regular diesel generator maintenance is crucial to ensure reliable and efficient operation. By following a maintenance checklist, schedule, and chart, as well as keeping a maintenance log book, you can ensure that all necessary maintenance tasks are completed on time and that any issues are identified and addressed promptly. While there are costs associated with regular maintenance, it can ultimately save you time and money by avoiding costly repairs and downtime.

Comments are closed.